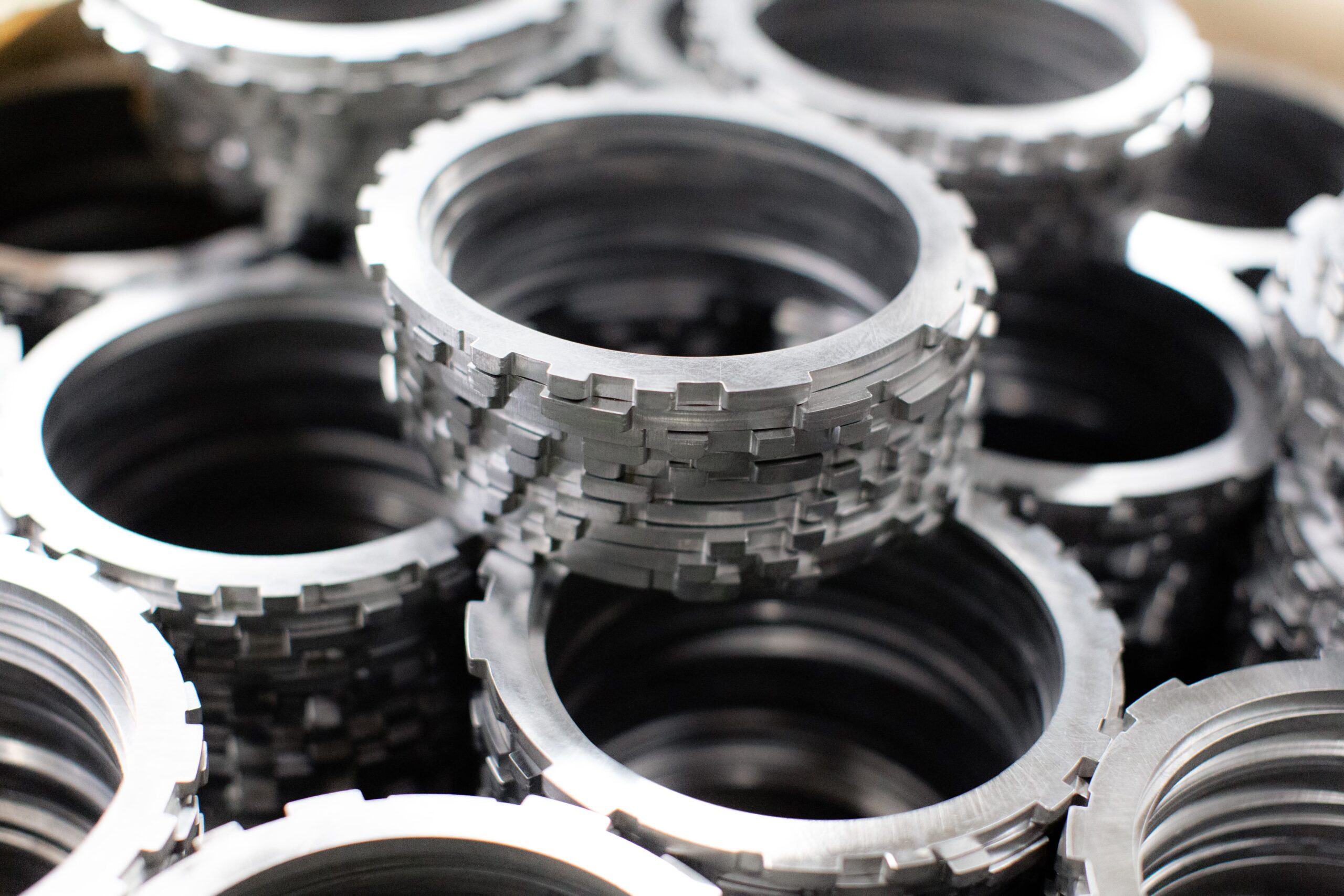

Fineblanking

Fineblanking is a triple action precision blanking process that uses presses to cold extrude metal parts into near “net shape” reducing expensive secondary finishing operations. Consistent flatness, complex shapes and profiles, true position, and superior edge condition. Higher precision at lower cost.

Conventional Stamping

Highly repeatable progressive and transfer stamping. All conventional stamping in Queretaro, Mexico. Press tonnages from 150T to 1500T. Competitive pricing.

Equipment overview

41 fineblanking presses ranging from 150T-1000T located in the US and Mexico.

0.1mm flatness tolerance held out of the press.

Strip widths from 40mm to 450mm

Part size up to 420mm

Thickness: 0.75mm-16mm steel, 20+mm Aluminum

Low and Medium Carbon steels, HSLA , Bi-metal, Copper, Inconel, Stainless Steel, and Aluminum